This 500KG/H Dry Garlic Peeling Production Line is specifically designed to solve the problems of high water consumption, high pollution, and garlic clove damage associated with traditional wet peeling methods. Utilizing pure dry pneumatic peeling technology at its core, it achieves an impressive single-line capacity of 500KG/H, with a stable peeling rate exceeding 99%. The entire garlic peeling line is constructed of food-grade stainless steel, ensuring hygienic and safe processing, making it an ideal choice for companies committed to efficient, environmentally friendly, and high-quality garlic processing.

Dry Garlic Peeling Working Process

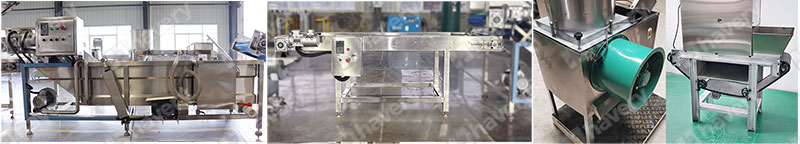

Raw material lifting → Garlic clove separation → Conveying → Garlic peeling → Finished product sorting

Raw material elevator: Used to evenly convey raw garlic to the clove separator.

Garlic clove separator: Separates whole garlic heads into cloves.

Conveyor: Conveys the garlic cloves to the peeling machine via the elevator.

Garlic peeling machine: Employs dry pneumatic peeling technology to efficiently remove the outer skin from the garlic cloves.

Finished product sorting machine: Separates the peeled garlic from the peeling scales.

Garlic Peeling Production Line Advantages

Zero Water Pollution: Compared to traditional alkaline or water-based peeling methods, the dry process completely avoids wastewater discharge, significantly reducing environmental treatment costs.

Ultra-Low Breakage Rate: The airflow peeling process involves zero mechanical friction on the garlic cloves, ensuring they remain intact after peeling. The breakage rate is far lower than traditional mechanical or water-based peeling methods.

Lower Operating Cost: Optimized pneumatic system design, while using an air source, results in lower overall energy consumption (electricity and water) compared to traditional wet processes, making long-term operating costs more competitive.

Simple Operation & Maintenance: The entire line utilizes a centralized electronic control system with a user-friendly interface, low failure rate, and simple and quick routine cleaning and replacement of vulnerable parts.

Garlic Peeling Processing Line Features

Pneumatic Dry Peeling Technology: Utilizes high-pressure airflow as the peeling power source, eliminating the need for heating or soaking in water, thus preserving the garlic cloves’ natural dryness.

High-Standard Stainless Steel Construction: All parts in contact with the garlic are made of AISI 304 food-grade stainless steel, which is corrosion-resistant, easy to clean, and meets international food hygiene standards.

High Capacity & Stability: Designed for a capacity of 500 kg/hour, the system employs variable frequency speed control to ensure long-term, continuous, and stable operation of the production line.

Modular Integrated Design: The entire system is compact, requiring minimal space. Each unit can be flexibly configured and quickly installed according to the customer’s factory layout.

Garlic Peeling Production Line Benefits

Extended Shelf Life: The high dryness of the garlic cloves, resulting from the absence of moisture during processing, facilitates subsequent storage, transportation, and further processing (such as garlic powder and garlic granules), significantly extending the product’s shelf life.

Enhanced Export Competitiveness: Meeting stringent international market requirements for food processing hygiene and environmental protection (such as HACCP/FDA) helps your products successfully enter high-end international markets.

Optimized Labor Costs: The highly automated production line requires only a small number of operators for monitoring and assisting with sorting, significantly reducing reliance on large numbers of manual laborers and lowering labor costs.

Quick Return on Investment: The combination of high capacity, high peeling rate, and low operating costs ensures higher yield and efficiency, enabling customers to recoup their equipment investment more quickly.

Conclusion

This industrial-grade 500KG/H dry garlic peeling production line, with its high peeling capacity, stable operation, and superior quality, is an ideal choice for improving garlic processing efficiency, reducing production costs, and enhancing product quality.

For more detailed information about this equipment, please leave a message online. Our professional team will be happy to assist you!