Description

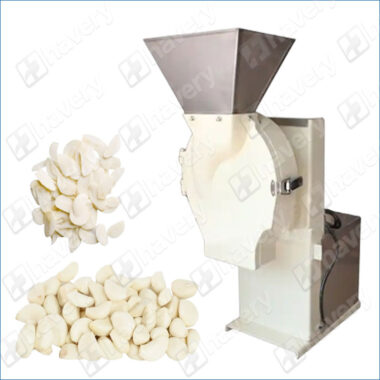

The Automatic Peeled Garlic Clove Washing and Drying Machine is a fully automated processing solution specially developed for handling peeled garlic cloves. Designed to meet the hygiene, quality, and efficiency requirements of modern food factories, this machine integrates high-pressure washing, impurity removal, and low-temperature drying into one continuous system. It ensures that peeled garlic cloves are thoroughly cleaned, surface-moisture removed, and delivered in a fresh, sanitary, and ready-to-process condition—ideal for garlic paste production, dehydrated garlic projects, and spice processing lines.

Garlic Cloves Washing Machine Working Principle

The equipment operates through a multi-stage cleaning and drying process:

-

Air-bubble washing: Peeled garlic cloves are lifted and washed using bubble agitation, efficiently removing dirt, film residues, and processing debris.

-

Spray rinsing: Clean water sprays apply secondary washing to ensure the cloves meet food-grade cleanliness.

-

Air-blowing & low-temperature drying: A high-pressure air knife removes surface moisture, followed by warm air drying that preserves freshness without overheating the garlic.

This combined process ensures uniform cleaning, sanitary operation, and stable drying results, perfectly suitable for peeled garlic clove production.

Garlic Washing And Drying Machine Features

1. Integrated Washing and Drying System

Combines air-bubble cleaning, spray rinsing, and hot-air drying for complete processing of peeled garlic cloves.

2. Food-Grade Stainless Steel Construction

All parts contacting garlic are made from SUS304 stainless steel, ensuring hygiene and corrosion resistance.

3. Adjustable Drying Temperature and Airflow

Allows precise drying settings to avoid overheating and maintain the natural aroma and freshness of peeled cloves.

4. Continuous Conveyor Design

Supports large-scale processing with stable feeding, smooth conveying, and consistent output quality.

Garlic Cleaning Machine Advantages

1. Gentle Cleaning for Peeled Garlic Cloves

Specialized washing system avoids excessive impact, reducing clove damage and maintaining good appearance.

2. Efficient Moisture Removal

Air knives and low-temperature drying efficiently remove surface water, improving shelf life and preventing microbial growth.

3. Easy To Operate & Maintain

Simple control panels, removable filters, and easy-to-clean water tanks reduce downtime and maintenance effort.

4. High Productivity for Industrial Use

Smart workflow enables continuous, fast, and large-capacity processing ideal for garlic manufacturers.

Garlic Washing And Drying Machine Benefits

1. Improved Final Product Cleanliness

Provides uniform and hygienic washing, making peeled garlic cloves meet export and food-grade processing standards.

2. Increased Production Efficiency

Reduces manual washing and drying labor, cutting costs and speeding up overall production.

3. Better Product Quality for Further Processing

Well-cleaned and properly dried garlic cloves are ideal for making garlic paste, garlic powder, seasonings, and frozen garlic products.

4. Stable and Consistent Output

Ensures batch-to-batch uniformity, improving product quality and enhancing factory competitiveness.

Conclusion

The Automatic Peeled Garlic Clove Washing and Drying Machine For Sale is a powerful and efficient solution for factories processing peeled garlic cloves at scale. With integrated cleaning and drying, gentle handling, and hygienic food-grade construction, it significantly improves product quality and production efficiency.

👉 Want detailed specifications, video demonstrations, capacity options, or pricing?

📩 Contact us or leave a message now — our team will send complete information immediately!