Description

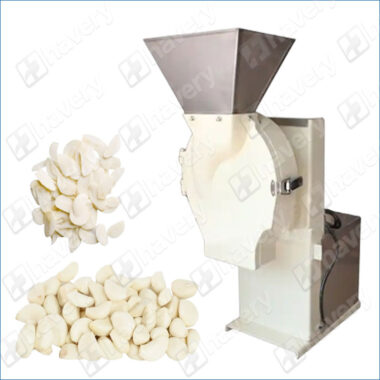

The Compact Dry Garlic Bulb Breaking Machine is a specialized piece of equipment designed for efficiently processing dry garlic bulbs, ensuring clean, uniform, and damage-free clove separation. This compact model is engineered for small to medium food factories, garlic processing workshops, and seasoning production lines that require high-precision breaking without soaking or manual labor. Its dry-type operation preserves the natural dryness, aroma, and shelf life of garlic cloves, making it ideal for downstream peeling, drying, slicing, or powder production.

Garlic Bulb Breaker Working Principle

The garlic bulb breaker works through a roller-gap squeezing and vibration separating system. When dry garlic bulbs are fed into the chamber, adjustable silicone rollers gently press the bulbs, causing the cloves to separate naturally without damaging their surfaces. A built-in vibration screen then removes loose outer skins and separates large, small, and whole cloves efficiently. The dry process ensures no moisture absorption, no contamination, and stable separation for industrial production.

Garlic Bulb Breaking Machine Features

1. Dry-Type Garlic Bulb Breaking System

Specially designed for dry garlic bulbs, maintaining natural dryness and preventing moisture-related spoilage.

2. Adjustable Roller Gap Design

Allows flexible separation for different garlic bulb sizes, ensuring precise and consistent clove separation.

3. Compact and Space-Saving Structure

Small footprint suitable for limited workshop spaces while supporting continuous industrial operation.

4. Stainless Steel Construction

Food-grade stainless steel frame ensures durability, hygiene, and long-term resistance to wear and corrosion.

Garlic Bulb Separating Machine Advantages

1. No Water Required

Fully dry separation avoids mold risk, improves storage stability, and lowers operational costs.

2. Low Damage to Garlic Cloves

Soft rubber rollers and optimized pressure design protect cloves from breakage during separation.

3. Easy to Operate & Maintain

Simple control panel, easy cleaning components, and minimal maintenance requirements support daily heavy use.

4. Compatible With Multiple Processing Lines

Ideal for feeding garlic peeling machines, drying lines, slicing machines, powder lines, and packaging systems.

Benefits

1. Higher Output Quality

Uniformly separated cloves improve the efficiency and yield of later processing steps such as peeling and drying.

2. Reduced Labor Dependency

Eliminates manual bulb cracking, reducing labor costs by up to 70% and improving production efficiency.

3. Improved Cleanliness & Hygiene

Dry operation keeps cloves clean and free from moisture, supporting food-grade processing standards.

4. Increased Production Capacity

High-speed breaking mechanism supports continuous feeding and meets the needs of fast-paced industrial production.

Conclusion

The Compact Dry Garlic Bulb Breaking Machine for Garlic Clove Separating offers a reliable and efficient solution for dry garlic processing factories seeking clean, precise, and damage-free clove separation. With its dry operation, adjustable rollers, compact design, and industrial-grade build, it is an essential first-step machine in modern garlic processing lines.

👉 Want more details about machine capacity, models, price, or custom solutions?

📩 Leave us a message now — our specialists will reply with full specifications and a tailored quotation!