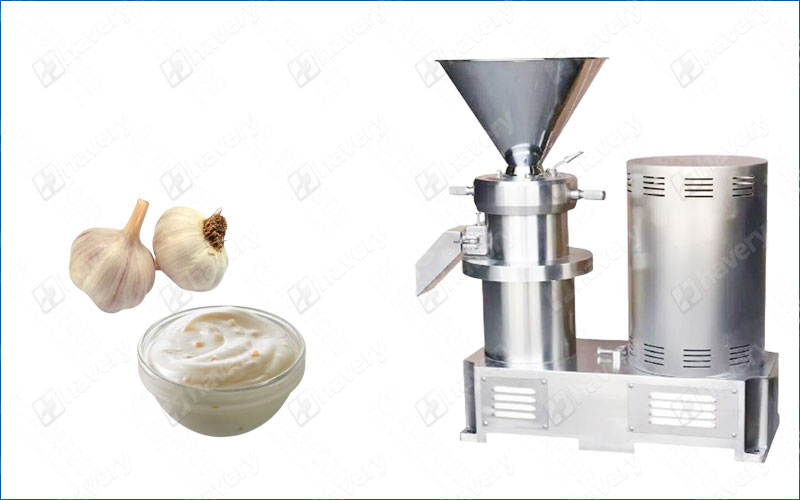

In the food processing industry, producing smooth, uniform, and flavorful ginger and garlic paste relies on a core piece of equipment: the colloid mill. For businesses looking to enter or expand their ginger and garlic paste production, the “Ginger Garlic Paste Making Machine Price” is a crucial decision-making factor. The ginger garlic paste making machine price range for these specialized machines typically varies from thousands to tens of thousands of US dollars, reflecting significant differences in professionalism, configuration, capacity, and automation levels. A basic, small-scale colloid mill might cost only a few hundred dollars, while a fully automatic, high-capacity, integrated production line meeting strict hygiene standards can cost tens of thousands of dollars. Understanding the factors behind the price is essential for making a worthwhile investment.

The core factors influencing the “Ginger Garlic Paste Making Machine Price” can be summarized into two main aspects: the machine’s specialization (i.e., the depth of design tailored to the characteristics of ginger and garlic paste) and the machine’s specific hardware and software configuration. These factors directly determine the equipment’s efficiency, product quality, and long-term operating costs.

Factor One: The Professionalism of the Machine – Designed Specifically to Conquer the Unique Challenges of Ginger and Garlic Paste Production

A truly professional ginger and garlic paste colloid mill differs fundamentally from general-purpose grinding equipment. It doesn’t simply crush the ginger and garlic; instead, it provides engineered solutions tailored to the characteristics of the raw materials. This “professional knowledge” is embedded in the equipment and is a crucial component of its value.

Grinding Technology for High-Fiber and High-Viscosity Materials:

Ginger is rich in crude fiber, while garlic contains viscous substances. Ordinary blenders struggle to completely break down the fibers and achieve ultra-fine homogenization, often resulting in coarse particles and a stringy texture in the paste. Professional colloid mills utilize ultra-high shear force principles, employing a precise rotor and stator structure to create intense physical shearing, impact, and cavitation within a tiny gap. This instantly micronizes the ginger fibers and evenly disperses the viscous substances in the garlic, ultimately producing an extremely smooth, creamy, and uniformly textured ginger and garlic paste – this is the key to its premium quality.

Temperature Control System for Stable Flavor and Color:

The grinding process of ginger and garlic generates heat due to friction. Excessive temperatures accelerate the volatilization of flavor compounds (especially the pungent aroma of garlic) and can lead to oxidation and discoloration of the paste, causing it to lose its fresh green or milky white color. High-end equipment integrates an efficient cooling system (such as jacketed water cooling or circulating cooling) to ensure that the grinding process takes place at low temperatures, maximizing freshness and maintaining the product’s vibrant color and rich, pure flavor. This system directly increases the complexity and cost of the machine.

Hygienic Design for Processing Oily and Viscous Materials:

Ginger and garlic paste is viscous and contains vegetable oils, which can easily adhere to dead corners of the equipment, promoting bacterial growth and causing cross-contamination. Professional colloid mills use 316L stainless steel throughout, with mirror-polished inner walls and smooth, crevice-free welds, meeting food hygiene standards. Their structural design facilitates quick disassembly and cleaning (CIP/SIP functionality), ensuring hygienic safety for each production batch and meeting the quality control requirements of export or high-end brands. This design, specifically tailored for the hygienic safety of these particular materials, is something that basic equipment lacks.

Factor Two: The Machine’s Core Configuration – Determining Production Capacity, Durability, and Control Precision

Price differences are most directly reflected in the “hard power” of the equipment. From the core power source to the contact parts, different configurations determine the machine’s production capacity ceiling and lifespan.

Motor Power and Grinding Head Structure (Core Power):

Motor Power: Directly determines production capacity and efficiency in processing hard raw materials. Small machines may be equipped with a 2.2kW motor, suitable for small-batch workshops; while large continuous production equipment can have motor power of 55kW or more, capable of processing tons of raw materials per hour. Higher power means higher price.

Grinding Head Structure: Colloid mills have various tooth structures (such as helical teeth, straight teeth, and perforated types) and multi-stage combinations for the rotor and stator. For ginger and garlic paste, a multi-stage fine grinding combination (coarse grinding, fine grinding, ultra-fine grinding) can achieve better fineness in a single processing step. More complex and precise grinding head combinations mean higher manufacturing costs and better product quality.

Materials and Manufacturing Process (Foundation of Durability):

Contact Part Materials: The minimum standard is food-grade stainless steel 304. Higher-end equipment uses stainless steel 316L, which has stronger corrosion resistance, especially against sulfides in ginger and garlic, resulting in a longer service life and ensuring no metal contamination of the product.

Key Component Processing: Core grinding components such as the rotor and stator are manufactured using forging and precision CNC machine tools, ensuring dynamic balance and extremely high fitting accuracy. This not only affects grinding fineness but also directly relates to the equipment’s smooth operation, noise level, and mechanical seal lifespan. Inferior craftsmanship can lead to leakage, rapid wear, and increased maintenance costs.

Automation and Control Level (Efficiency and Consistency Guarantee):

Basic models may only have a single switch. Mid-to-high-end equipment integrates a variable frequency control system, allowing operators to steplessly adjust the grinding shaft speed, thus flexibly controlling the shear force and output fineness to adapt to variations in different batches of raw materials.

Fully automatic production lines are more likely to be equipped with PLC touch screen control, which can preset and store process parameters for different products (such as time, speed, and temperature), enabling one-button standardized production, greatly reducing human error and ensuring consistency between product batches. The inclusion of automated control systems significantly increases equipment prices, but also brings long-term benefits in terms of labor savings and consistent quality.

Conclusion

In summary, the “Ginger Garlic Paste Making Machine Price” is not an isolated figure, but rather a comprehensive monetary reflection of the equipment’s professionalism, production capacity, durability, and intelligence level. Investing in a professional colloid mill is essentially investing in the ultimate quality of your ginger and garlic paste products – unparalleled smooth texture, locked-in fresh flavor, stable color, and the efficiency and hygiene of large-scale production.

Choosing the right equipment lays the foundation for your brand’s competitiveness and profitability. Do not let the initial price be the sole decision factor; instead, consider the long-term operating costs and output value.

We hope this article provides you with clear insights!

What other questions have you encountered when purchasing ginger and garlic paste production equipment? Are you more concerned about equipment pricing at a specific production capacity, or do you need a deeper understanding of certain technical details (such as how to completely eliminate fiber residue)? Please share your thoughts or questions in the comments section below!

If you found this analysis helpful, please like, share it with your industry network, or share it with partners who may be facing equipment selection challenges. Your interaction can help more industry professionals make informed decisions.