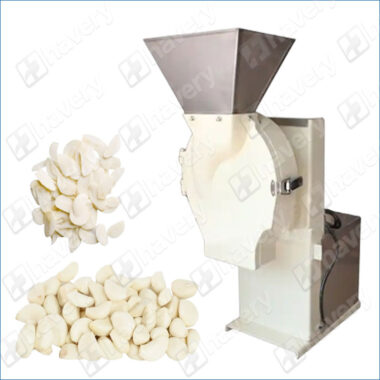

Description

The garlic peeling machine is a highly efficient and fully automated solution designed specifically for processing dry garlic at industrial scale. Unlike traditional wet-type peeling methods that require soaking, this dry-type machine uses advanced airflow and pneumatic techniques to remove garlic skins cleanly, ensuring the cloves remain dry, intact, and ready for further processing. It is ideal for garlic powder production lines, dehydrated garlic product factories, spice manufacturers, and food processing plants that demand clean, undamaged cloves with long shelf life.

Garlic Peeler Machine Working Principle

This garlic peeler machine adopts a compressed-air peeling mechanism combined with a vortex separation system. When dry garlic enters the peeling chamber, high-pressure air flows instantly loosen the outer skins by breaking the bond between the garlic skin and the clove membrane. The separated skins are removed through a cyclone dust collector, while the peeled cloves are automatically discharged for sorting or packaging.

This method ensures no water, no chemical additives, low damage, and high peeling efficiency, making it ideal for dry garlic processing environments.

Garlic Peeling Machine Features

1. Dry-Type Pneumatic Peeling Technology

Uses high-pressure airflow to peel dry garlic cloves without soaking, maintaining the natural dry state of the product.

2. Low Breakage Peeling Chamber

Specially engineered chamber reduces friction and collision, ensuring cloves remain intact during the peeling process.

3. Stainless Steel Industrial Build

Made of food-grade stainless steel, resistant to corrosion and suitable for long-term continuous operation in food factories.

4. High Output & Continuous Operation

Supports large-capacity feeding and 24/7 working mode, ideal for medium to large-scale garlic production lines.

Dry Garlic Peeling Machine Advantages

1. No Water Consumption

The dry processing system eliminates soaking, reducing operating costs and preserving the natural quality of dry garlic.

2. Cleaner & More Hygienic Production

Airflow peeling avoids microbial contamination commonly caused by wet methods, resulting in safer end products.

3. Reduced Labor Cost

Fully automatic feeding, peeling, and discharging minimize manual handling, improving overall production efficiency.

4. Longer Machine Life

Less contact with moisture and chemicals ensures lower maintenance frequency and longer service life.

Garlic Peeler Benefits

1. Improved Product Quality

Low breakage rate ensures more whole garlic cloves, which increases output value for garlic flakes, granules, and powder production.

2. Higher Processing Efficiency

Fast peeling speed means more batches can be completed in less time, supporting rapid order fulfillment.

3. Suitable for Diverse Garlic Products

Perfect for dry garlic cloves used in garlic powder, dehydrated garlic flakes, garlic granules, and seasoning industries.

4. Consistent and Standardized Results

Guarantees uniform peeling quality, making the final product more competitive in the food processing market.

Conclusion

The Industrial Dry Garlic Peeling Machine with Low Breakage Rate is an ideal solution for any food processing facility seeking efficient, hygienic, and cost-saving dry garlic peeling. Its advanced airflow peeling technology, low damage rate, and industrial-grade durability make it an essential upgrade for modern garlic processing lines.

👉 Want to know more about machine specifications, capacity options, prices, or custom solutions?

Contact us now or leave your message online — our professional team will send you full details immediately!